Note: This article provides a general overview of the BMW E9x fuel system and offers a few reliable upgrade paths for LS swaps. There are many ways to configure a fuel system for an LS swap, but these examples represent straightforward setups that have been tested and shown to work effectively.

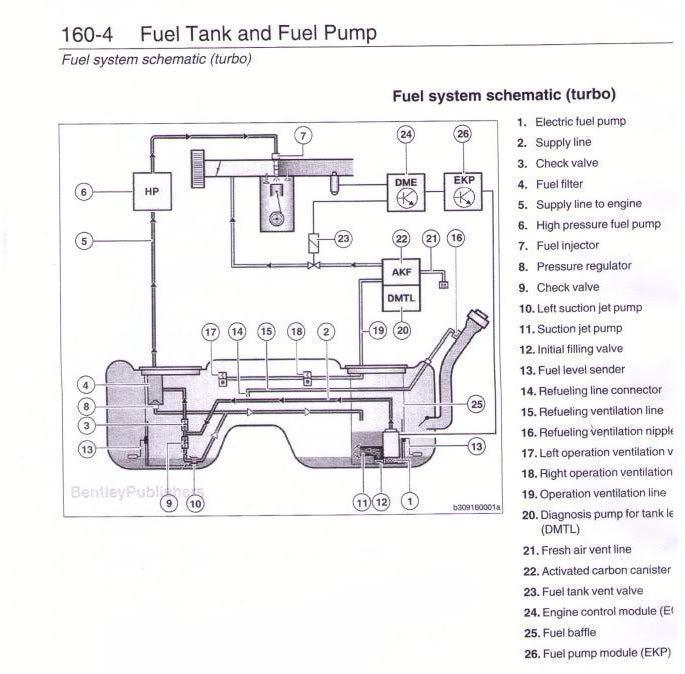

Understanding the Stock BMW Saddle Tank System

The BMW E9x chassis utilizes a saddle-style fuel tank, designed with two compartments connected by a siphon (venturi) system. This design maintains a low center of gravity and distributes weight evenly across the chassis, essential for handling and stability. Here’s how the system operates:

- Fuel Pump Location: The primary in-tank fuel pump is located on the passenger-side fuel hat. This pump not only supplies pressurized fuel to the engine but also powers the venturi system that transfers fuel across the tank.

- Fuel Level Equalization: Because the tank is divided into two compartments, the venturi system siphons fuel from the driver side back to the passenger side, keeping levels balanced. However, as fuel is continuously transferred to the passenger side, the driver-side sump will be the first to empty.

- Returnless System: The E9x chassis uses a returnless fuel system, with the fuel pressure regulator and return line built into the driver-side fuel hat. This configuration controls pressure within the tank itself, delivering fuel to the engine through a single 5/16" (8mm) female EFI quick-disconnect line.

- Fuel Pressure: The stock fuel system is designed to produce a static 72 psi of fuel pressure, which is not referenced from any vacuum or boost source. This fixed pressure is suitable for the stock engine, but higher-performance applications often require adjustments to maintain consistent delivery.

While effective for the stock BMW engine, an LS engine swap—especially at higher power levels—often demands upgrades to ensure reliable fuel flow and pressure.

BMW EKP Module and Fuel Pump Control

Function of the EKP Module in the Stock Configuration

In the BMW E9x, the EKP (Electronic Fuel Pump Control Module) dynamically controls fuel pump power based on engine demands, optimizing fuel delivery and efficiency. It receives commands from the factory ECU, adjusting the fuel pump’s speed and limiting current to prevent overload.

Limitations of the EKP Module with LS Swaps

With an LS swap, especially when using aftermarket ECUs like Holley, the EKP no longer receives proper signals from the BMW ECU. This can lead to:

- Reduced Fuel Pump Output: Without control signals, the EKP may restrict current to the pump, causing fuel starvation, especially under high demand.

- Inconsistent Power Delivery: Upgraded fuel pumps may not receive the necessary current, limiting their performance.

Using the EKP with MaxxECU Systems

For swaps using a MaxxECU, the EKP can be retained, as MaxxECU supports full control over the EKP module. This setup allows the EKP to regulate fuel pump output properly, provided the fuel pump is compatible with the EKP’s current capacity.

- Current Limitations: The EKP is designed to handle the current draw of stock or moderately upgraded pumps but may struggle with high-output pumps. When using the EKP with MaxxECU, ensure the selected fuel pump’s current draw aligns with the EKP’s capacity to avoid potential issues.

Replacing the EKP Module with a Relay

To ensure reliable fuel pump operation, bypass the EKP and control the pump with a relay triggered by the LS ECU:

- Relay Setup: Replace the EKP with a standard relay that the LS ECU can activate, providing direct on/off control for the fuel pump.

- Stable Power Supply: This setup delivers consistent power to the fuel pump, eliminating the current restrictions of the EKP.

Fuel System Upgrades for Different Power Levels

Depending on your target horsepower, various upgrades can ensure sufficient fuel supply and pressure for an LS engine in the E9x chassis:

Stage 1: Up to 400 HP

For mild LS swaps up to 400 horsepower, the stock BMW fuel system can often be modified with minimal upgrades:

- Retain Returnless with Stock Fuel Lines and Fuel Filter: The factory fuel lines and filter can support this power level without requiring modifications.

- Aftermarket Fuel Injectors: Choose injectors rated for LS engines that are compatible with the LS wiring harness.

Stage 2: 400-600 HP

For builds in the 400-600 HP range, modifications to the saddle tank setup are recommended to meet higher fuel flow requirements:

- High-Capacity In-Tank Pump: Install a high-capacity in-tank pump, such as a Walbro 450 or other capable pump, to handle higher fuel demands.

- Consider a Return style system: Aftermarket lines and regulator can be added with a return line to the passenger side top hat if lower fuel pressure or boost referenced fuel pressure is required.

- Upgraded Fuel Rails and Injectors: Use fuel rails designed for LS engines and injectors rated for this power level, typically 42-60 lb/hr (depending on fuel used)

Stage 3: 600+ HP

For LS swaps exceeding 600 HP, a comprehensive fuel system upgrade is necessary to prevent fuel starvation under high loads. Here are two reliable options for high-power applications:

Option 1: Dual In-Tank Pumps with Upgraded Driver-Side Top Hat

This setup retains the stock saddle tank configuration but upgrades the in-tank pumps and the driver-side top hat:

- Dual In-Tank Pumps: Install dual high-capacity in-tank pumps (such as dual Walbro 450 pumps) to provide sufficient fuel flow at high horsepower levels. This setup allows one pump to operate under normal conditions, with the second pump activating when higher fuel demand is detected.

- Upgraded Driver-Side Top Hat: Replace the driver-side fuel hat with an upgraded version that removes the stock venturi, regulator, and filter restrictions. This modification ensures unrestricted fuel flow to meet the demands of a high-output LS engine.

- Fuel Pressure Regulator: Moving the fuel pressure regulator closer to the engine provides more consistent pressure control at the rails.

- Additional Considerations: This configuration maximizes the capabilities of the BMW tank system but requires modifications to bypass the stock venturi and regulator in the driver-side top hat, which can restrict flow at high pressures.

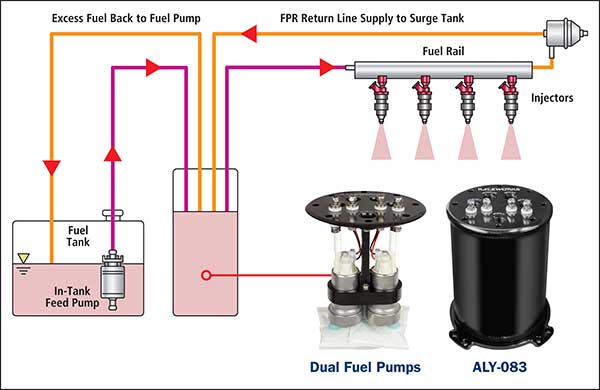

Option 2: Surge Tank System

A surge tank setup provides consistent fuel delivery under extreme conditions, such as high lateral G-forces, and is an ideal choice for high-power applications.

- How a Surge Tank Works: A surge tank acts as a secondary fuel reservoir, ensuring a steady fuel supply to the engine, even if fuel in the main tank sloshes away from the in-tank pump pickup during hard acceleration or cornering. The surge tank remains full as it is constantly refilled by the in-tank pump(s), regardless of fuel level or movement in the main tank.

- Maintaining Stock Tank Components: This setup preserves the entire stock BMW fuel tank and both top hats. You can keep either the stock in-tank pump or an upgraded high-capacity pump in the main tank, depending on power needs.

- Fuel Pressure Regulator: Install a fuel pressure regulator in the engine bay to maintain precise pressure at the injectors.

- Plumbing Requirements: A surge tank setup requires additional lines and fittings:

- Feed Line: The in-tank pump supplies fuel to the surge tank.

- Return Line: An overflow return line is added from the surge tank back to the passenger-side hat in the main tank to manage excess fuel.

- Fuel Lines to Engine Bay: Fuel lines from the surge tank supply pressurized fuel to the engine, regulated by the FPR near the injectors.

- Additional Benefits: A surge tank prevents fuel starvation caused by fuel sloshing within the saddle tank. It provides consistent fuel pressure even under hard driving conditions, making it ideal for high-performance applications.

Both options offer reliable solutions to support high-output LS swaps in the BMW E9x chassis. The dual in-tank pump system is ideal for those seeking to maximize the stock tank’s capabilities, while the surge tank provides added protection against fuel starvation during extreme driving conditions. Select the system that best aligns with your performance goals and driving style to ensure reliable fuel delivery and optimal engine performance.

Common modifications

Return bulkhead on passenger side

6an efi quick connect fitting on driver side feed line